Leave Your Message

In today's competitive market, selecting the right machine for packaging is crucial for business success. According to a report by Smithers Pira, the global packaging machinery market was valued at $47 billion in 2020 and is projected to reach $65 billion by 2026. This growth is driven by increasing demand for efficient, sustainable, and automated packaging solutions across various industries. Choosing an appropriate machine for packaging not only improves operational efficiency but also enhances product presentation.

Businesses must carefully assess their specific needs when investing in packaging machinery. Factors such as product type, production speed, and packaging material play a significant role in decision-making. A detailed analysis of current demands can reveal gaps in existing packaging capabilities. Operators might find that they require machines that can handle a range of package styles. This could lead to a re-evaluation of their machinery choices. While various models are available, the most suitable machine for packaging should align with both current operational goals and future growth plans.

However, there is room for improvement in the selection process. Many companies face challenges in adapting to rapid technological advancements. A machine for packaging that seemed ideal yesterday may quickly become outdated. This highlights the importance of ongoing evaluation and flexibility in machinery investments. Businesses should adopt a proactive approach to avoid common pitfalls and stay ahead in the evolving packaging landscape.

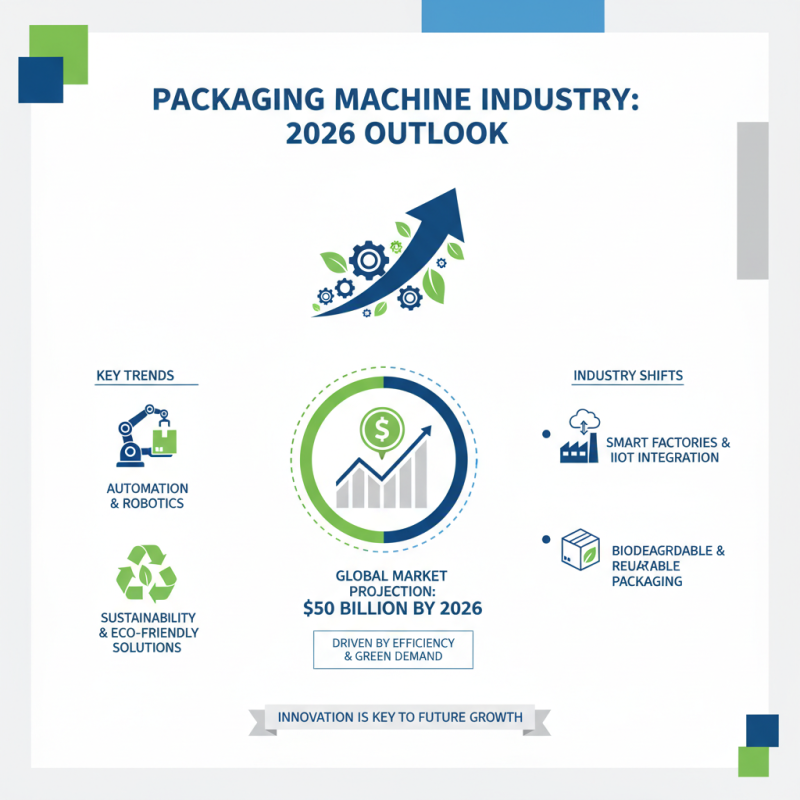

The packaging machine industry is evolving rapidly, driven by trends like automation and sustainability. In 2026, we see significant shifts in how businesses approach their packaging needs. According to a recent report, the global packaging machinery market is projected to reach $50 billion by 2026, emphasizing the importance of innovation in this field. This growth is largely due to increased demand for efficient and eco-friendly packaging solutions.

Automation remains a key trend. Businesses are investing in smart machines that enhance production efficiency. These machines allow for faster turnaround times and can adapt to different package sizes easily. However, not every business has the resources to upgrade. Smaller companies might struggle to keep pace with these advancements, highlighting a potential gap in technological accessibility.

**Tip:** Consider your budget before investing in new technology. Research various options and choose one that fits both your needs and financial capacity.

Sustainability is another crucial factor. Customers now prefer brands that prioritize eco-friendly materials. A report indicates that 67% of consumers are willing to pay more for sustainable packaging. Still, businesses face challenges in sourcing these materials and may sacrifice quality for sustainability. This can lead to waste and inefficiency in the long run.

**Tip:** Test out eco-friendly materials on a small scale before committing to larger production runs. This helps ensure quality and sustainability align.

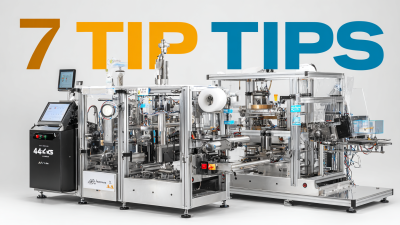

When choosing packaging machines, each type offers distinct advantages. For instance, vertical form-fill-seal machines are excellent for snacks and powders. They are fast and efficient. However, they may require skilled operators for optimal performance. Issues with calibration can arise, impacting production rates.

On the other hand, automatic labelers provide precision and speed for bottle packaging. They enhance brand identity through consistent labeling. Still, these machines might struggle with irregular bottle shapes. Adjustments can be time-consuming, proving challenging for some users.

The pros and cons often depend on industry-specific needs. For instance, food businesses may prioritize hygiene and speed. In contrast, cosmetic industries might focus on aesthetics and innovation. Recognizing these nuances is essential for making informed decisions. Each machine type has its quirks that require attention and adjustments over time.

This bar chart provides a visual comparison of various types of packaging machines based on their pros and cons ratings. Each type's rating indicates its overall effectiveness and suitability for different business needs in the packaging industry.

The packaging machine market is witnessing notable growth. By 2026, it's projected to reach $45 billion. This figure represents a compound annual growth rate (CAGR) of around 6%. Industries like food, beverages, and pharmaceuticals are driving this demand. Companies are investing in advanced technologies for better efficiency and sustainability.

Flexibility is crucial for modern packaging machines. As consumer preferences shift, manufacturers need machines that adapt to new product formats quickly. The rise of e-commerce is also influencing packaging needs. More products require safe, durable, and easy-to-open packages. Data from industry reports indicate a significant increase in automated packaging machinery. These machines can reduce labor costs and enhance productivity.

However, not all businesses can keep pace. Smaller firms may struggle with high initial investments. They often lack access to advanced technology. This gap could hinder their growth and competitive edge. The market demands innovation, yet implementation can be a challenge. Embracing new solutions is vital, but it's essential to assess specific needs carefully.

| Machine Type | Market Demand (Units) | Growth Rate (CAGR) | Key Features |

|---|---|---|---|

| Horizontal Flow Wrappers | 150,000 | 5.2% | Versatile for various products, high speed, efficient sealing. |

| Vertical Form Fill Seal Machines | 120,000 | 6.5% | Compact design, suitable for granules, powders, and liquids. |

| Labeling Machines | 200,000 | 4.8% | Accurate labeling, high-speed operation, suitable for various shapes. |

| Case Packing Machines | 90,000 | 5.0% | Automated case packing, reliable performance, various pack styles. |

| Cartoning Machines | 70,000 | 3.9% | Fast operation, flexibility for different carton sizes. |

Efficiency and cost-effectiveness are crucial when selecting packaging machines for businesses. According to industry reports, companies can reduce packaging costs by 30% with advanced machines. These machines often include features like automated feeding systems and speed adjustments. Integration of technology enhances productivity so your workforce can focus on other areas.

High-performance machines typically yield faster output rates. Studies indicate that automated packaging systems can process up to 50% more products than manual methods. However, these machines may require a significant upfront investment. A careful analysis of ROI is vital. Not all businesses can easily absorb the high costs associated with the latest technology.

Another essential feature is energy efficiency. Machines that consume less power can lower operational costs over time. However, not all energy-efficient models deliver the expected savings. An informed decision hinges on evaluating both performance data and real-world experiences. Investing in equipment without understanding these factors could lead to unsatisfactory results. Balancing efficiency with affordability should be a priority for every business.

Sustainability in packaging is rapidly gaining importance in various industries. Businesses are increasingly seeking eco-friendly materials that minimize environmental impact. Many companies now use biodegradable plastics, recycled paper, and compostable materials. These alternatives reduce waste and contribute to a circular economy, but challenges remain.

To meet regulations on sustainability, companies must adapt. New laws aim to limit single-use plastics, pushing businesses toward innovative solutions. Yet, this transition can be difficult. Sourcing sustainable materials often leads to higher costs. Some businesses may struggle to find reliable suppliers. Others face technical challenges in packaging design.

Introducing new eco-friendly solutions requires time and investment. Employees may need training to implement these changes effectively. Consumers are becoming more conscious of sustainability, creating demand. However, businesses must ensure that eco-friendly endeavors do not compromise product quality. Striking this balance is crucial for success.