Leave Your Message

Efficient packaging is vital for modern businesses. In 2023, the global packaging machinery market was valued at over $45 billion. This figure is projected to grow significantly by 2026. Companies are increasingly incorporating Packaging Machines to streamline operations and reduce costs.

Integrating advanced Packaging Machines can improve productivity. Automation in packaging can increase output by as much as 30%. Many businesses still rely on manual processes. This reliance can lead to inefficiencies and error rates of up to 5%. Companies must reflect on their current methods to assess areas for improvement.

Investing in the right Packaging Machines is essential. The choice of machinery can greatly impact a company's bottom line. A poorly chosen machine can cause delays and increased labor costs. As industries evolve, so should packaging solutions, prompting businesses to rethink their strategies.

Packaging machines play a crucial role in enhancing business efficiency. Their automated processes save time and reduce human error. According to industry reports, over 30% of production time can be lost due to manual packaging. This inefficiency drives the need for investing in modern machines. They streamline operations and improve output quality.

Businesses using advanced packaging solutions can see a significant return on investment. A recent study showed that companies utilizing automation experienced a 25% increase in production rates. This leads to more products reaching market faster. Moreover, packaging machines can adapt to various product sizes and shapes, offering flexibility crucial for modern demands.

Tip: Regularly assess your packaging needs. Adapting technology can lead to enhanced efficiency. Remember, investing in quality over cost may yield better long-term gains. Think about future scalability when choosing equipment. Do not overlook maintenance either. An unmaintained machine can lead to costly downtime, impacting your overall production.

When selecting modern packaging machines, certain features enhance business efficiency significantly. One key aspect is automation. Automatic machines reduce labor costs by up to 30%. They also minimize human error, leading to fewer product defects and waste. Advanced machines adapt to different packaging types quickly. This flexibility can increase production rates, contributing to better overall efficiency.

Another vital feature is speed. High-speed packaging machines can achieve rates exceeding 300 products per minute. This capability meets the growing demand in various industries. Moreover, energy efficiency is crucial. Machines that use less energy help decrease operating costs. According to industry studies, energy-efficient systems can lower energy consumption by 20-50%.

Finally, user-friendly interfaces are essential for operation and maintenance. Simple controls reduce training time for new staff. Yet, despite these advancements, some businesses still struggle with integration. Transitioning to new equipment often presents challenges, such as compatibility with existing systems. Reflecting on these potential issues can lead to more informed decisions, ensuring better returns on investment.

As businesses look toward 2026, the demand for efficient packaging solutions skyrockets. Industry reports indicate that automating packaging processes can increase productivity by over 30%. Companies that adopt advanced packaging machinery report significant reductions in labor costs and waste. This trend reflects a broader movement toward optimizing supply chains and enhancing consumer satisfaction. High-speed packaging machines are capable of handling various products, from fragile items to bulk goods.

Top packaging machine brands are focusing on sustainability and smart technology. Many machines now come equipped with AI capabilities. This technology allows for real-time adjustments, leading to less downtime and minimal waste. According to recent data, about 75% of manufacturers are investing in eco-friendly materials and processes. Yet, the transition isn’t always smooth. Some businesses struggle with integrating new systems into existing workflows.

Investing in packaging machinery can be daunting. The initial costs may deter some companies. However, long-term benefits often outweigh these expenses. A study showed that firms experiencing delays in upgrading can lose market share. Observation and constant refinement are necessary. Adopting new technology demands a careful assessment of specific needs and capabilities. By doing so, businesses can truly boost efficiency and sustainability in 2026.

| Machine Type | Automation Level | Production Speed (units/min) | Energy Efficiency (kWh/unit) | Price Range (USD) |

|---|---|---|---|---|

| Horizontal Flow Wrapper | Fully Automatic | 60 | 0.15 | $25,000 - $40,000 |

| Vertical Form Fill Seal | Semi-Automatic | 80 | 0.10 | $15,000 - $30,000 |

| Stretch Wrapper | Fully Automatic | 30 | 0.20 | $20,000 - $35,000 |

| Case Packer | Fully Automatic | 45 | 0.25 | $30,000 - $50,000 |

| Labeling Machine | Semi-Automatic | 120 | 0.05 | $10,000 - $25,000 |

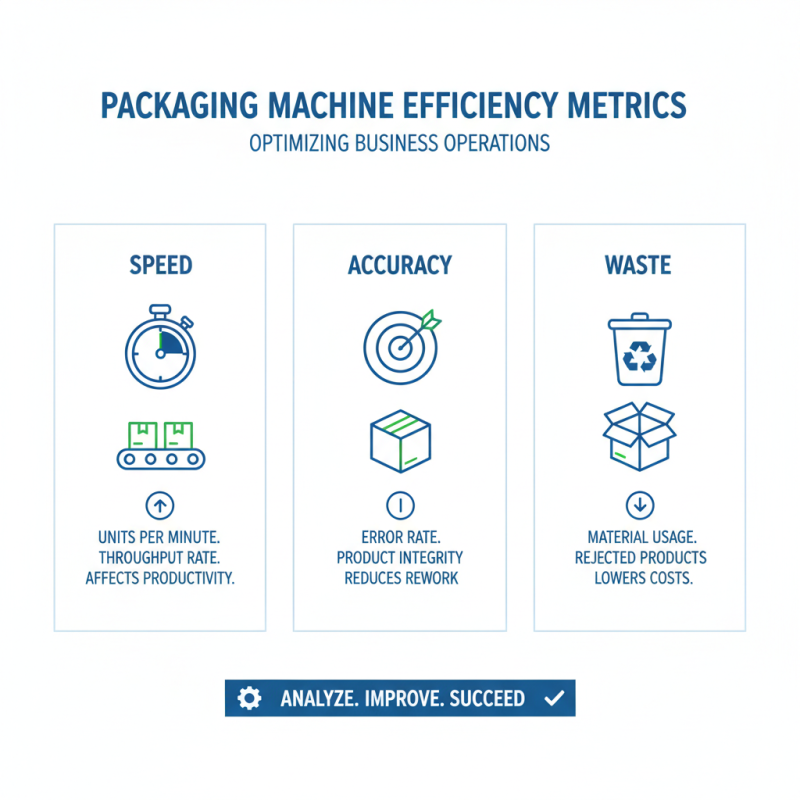

Efficiency metrics play a crucial role in understanding the impact of packaging machines on business operations. Businesses can track various metrics, such as speed, accuracy, and waste. By analyzing these metrics, companies can identify inefficiencies in their packaging lines. For instance, a machine that operates at a lower speed than expected can significantly affect productivity. Tracking these speeds helps highlight areas needing improvement.

Furthermore, accuracy in packaging directly influences customer satisfaction. Misleading packaging can lead to returns. Measuring error rates offers insights into a machine's reliability. Waste is another metric to consider. Excess materials can inflate costs. Businesses must evaluate how much waste their machines produce. Implementing changes based on these insights might enhance overall efficiency.

However, not all machines might perform as expected. Some may require more maintenance than anticipated. This can lead to downtime, impacting productivity. Reflecting on these performance issues is essential for long-term improvements. Regular assessments of machine performance can help businesses make informed decisions. Balancing efficiency and the potential for errors is key to achieving operational success.

The packaging industry is evolving rapidly, influenced by technology and sustainability concerns. Companies are exploring smart packaging solutions. These innovations include automation and digital printing, enhancing workflow efficiency. Smart sensors can now track freshness and temperature. This means products can reach consumers in optimal condition.

Investing in specialized machines can streamline packaging processes. However, not all businesses may find the latest technology cost-effective. Challenges exist in training staff to use advanced systems. Many companies are still struggling with outdated methods. This often leads to inefficiencies and waste.

Sustainability is another pressing issue. Many businesses are exploring biodegradable materials for packaging. Yet, the transition to sustainable options can be tricky. There are often trade-offs between durability and environmental impact. Adopting new technologies requires patience and reflection on current practices. Balancing efficiency with eco-friendliness will be essential for future success.