Leave Your Message

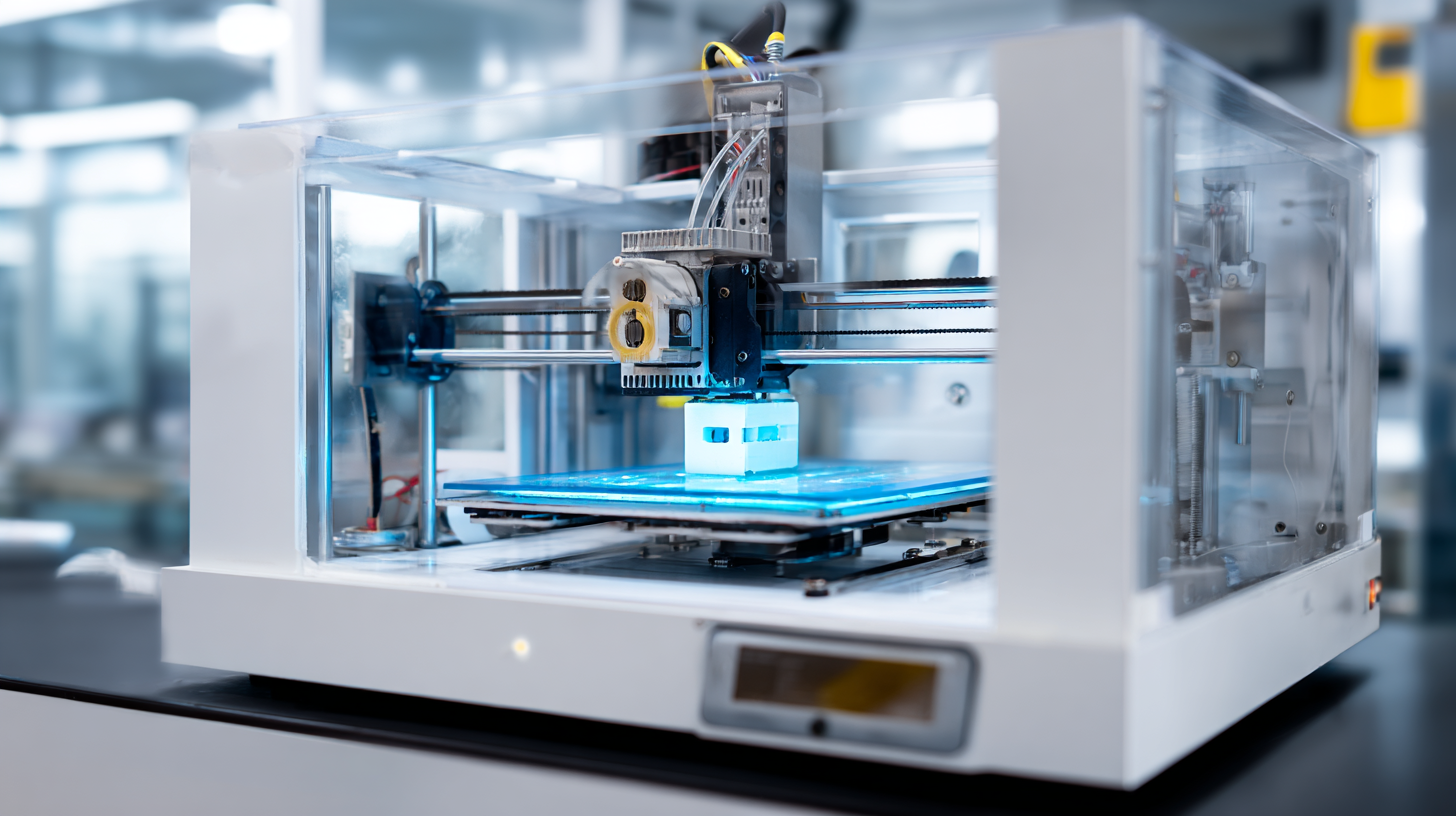

In today's competitive business landscape, choosing the right Label Printing Machine is crucial for optimizing efficiency and meeting customer demands. According to a recent report by Smithers Pira, the global label market is projected to grow at a CAGR of 4.5% through 2024, exceeding $50 billion in value. This growth underscores the increasing importance of high-quality labeling in branding and logistics, with businesses of all sizes needing to adapt. The right machine can streamline operations, reduce costs, and enhance product presentation. However, with a myriad of options available, including digital, flexographic, and thermal transfer printing technologies, making an informed choice requires a deep understanding of your specific needs and the capabilities of various machines.

As the demand for customized and sustainable labels rises, investing in the right Label Printing Machine can be a game changer for businesses aiming for future growth and sustainability.

When considering the right label printing machine for your business, understanding your specific requirements is paramount. Begin by assessing the volume of labels you need to produce. High-demand businesses may benefit from industrial-grade printers designed for heavy use, while smaller operations might find that a desktop model suffices. Additionally, consider the label sizes and formats that will be most frequently printed. Different machines accommodate various label dimensions, so choosing one that aligns with your needs will enhance efficiency and consistency.

Another crucial factor is the type of labels you wish to create. If your products require labels with intricate designs or vibrant colors, investing in a machine that supports high-resolution printing technology will be necessary. Evaluate whether you need waterproof labels, thermal printing capabilities, or special adhesives, as these features can significantly impact your machine choice. By clearly defining your label printing requirements, you can select a machine that not only meets your current needs but also accommodates future growth and changes in your business.

When evaluating different label printing technologies, it's essential to consider the specific requirements of your business. Each technology offers distinct advantages tailored for various applications. For example, thermal transfer printing is renowned for producing high-quality, durable labels suitable for outdoor use and extreme conditions. This makes it an excellent choice for industries that require robustness, such as logistics and manufacturing.

On the other hand, inkjet printing technology provides flexibility and vivid color output, which is ideal for businesses that prioritize aesthetically pleasing labels, such as retail and promotional products. However, it's important to note that inkjet labels may not withstand harsh environments as well as thermal transfer labels. Additionally, digital printing offers scalability and quick turnaround times, making it a desirable option for businesses that need to produce smaller batches of customized labels efficiently. By analyzing these technologies and aligning them with your operational needs, you can make an informed decision on the right label printing machine for your business.

When selecting the right label printing machine, it's essential to dive into the features and specifications that best align with your business goals. According to a report by Smithers Pira, the global label market is projected to reach $50 billion by 2025, highlighting the growing demand for customizable label solutions. A competent label printing machine should offer advanced features such as high-speed printing capabilities, versatility in label sizes, and compatibility with various materials. Machines that support digital printing techniques, for instance, provide better options for short runs and versioning, catering to businesses that require agility in their operations.

Additionally, consider the specifications that determine operational efficiency. For instance, machines with a higher print resolution (600 dpi or above) result in sharper images and clearer text, crucial for branding and compliance labels. The ability to integrate with software for design and inventory management can significantly enhance productivity. Studies show that businesses utilizing these advanced label printing solutions can reduce their production time by up to 50%, a compelling reason to invest in technology that not only meets current needs but also scales with future demands.

| Machine Type | Print Technology | Max Print Speed (IPM) | Max Print Width (inches) | Resolution (dpi) | Connectivity Options | Average Cost (USD) |

|---|---|---|---|---|---|---|

| Desktop Label Printer | Thermal Transfer | 5 | 4 | 300 | USB, Ethernet | $200 |

| Industrial Label Printer | Direct Thermal | 12 | 6 | 600 | USB, Ethernet, WiFi | $800 |

| Mobile Label Printer | Thermal | 4 | 2 | 203 | Bluetooth, USB | $150 |

| Label Printer for Small Office | Inkjet | 8 | 5 | 4800 | USB, WiFi | $300 |

| High-Volume Label Printer | Laser | 20 | 8 | 1200 | USB, Ethernet | $1500 |

When considering investing in a label printing machine, proper budgeting is critical to ensure a successful acquisition that meets your business's needs without straining your finances. First, evaluate the total cost of ownership, which includes not only the purchase price of the machine but also operating costs such as ink, materials, and maintenance. It's essential to research various models and their respective costs to establish a realistic budget that accommodates both initial and ongoing expenses.

Additionally, consider your production volume and growth projections. A higher initial investment in a more advanced machine might be justified if your business is poised for significant expansion. Look for features that will enhance efficiency and reduce long-term costs, such as higher print speeds and integrated software solutions. By aligning your budget with your business goals, you can make a more informed decision that balances upfront costs with the potential for increased profitability over time.

When selecting a label printing machine for your business, it’s crucial to not only consider the specifications and features but also the post-purchase support and maintenance options available. According to a recent industry report by Smithers Pira, nearly 30% of businesses faced operational downtimes due to inadequate after-sales support for their printing equipment. This statistic highlights the importance of choosing a supplier that provides robust maintenance services and reliable technical support.

One of the key tips for ensuring smooth operation post-purchase is to evaluate the warranty and service agreements offered by your supplier. Look for providers that offer comprehensive service packages, including preventative maintenance plans. As indicated by a study from Freedonia Group, companies that invested in routine maintenance experienced a 15% increase in their machinery's lifespan. Additionally, inquire about the availability of spare parts and their delivery timelines, which can significantly impact your ability to keep operations running efficiently.

Furthermore, assess the training resources that come with the machine. Many manufacturers offer training sessions or user manuals to help your team quickly adapt to new equipment. Ensuring your staff is well-trained can reduce error rates by up to 20%, according to recent findings published by the Label Industry Global Awards. Prioritizing these aspects will help you select a label printing machine that not only meets your operational needs but also supports long-term reliability and productivity.